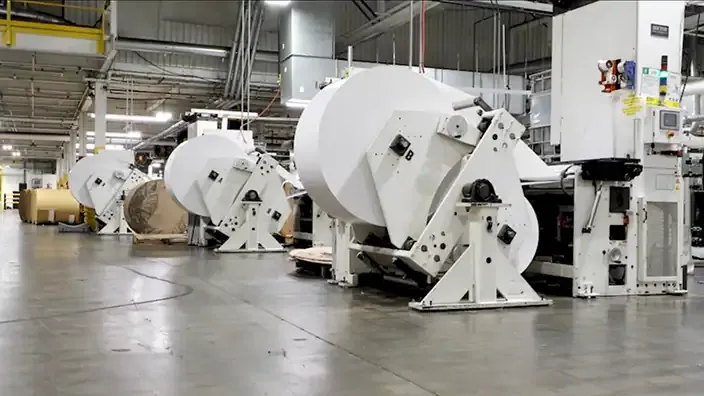

Our Manufacturing Facility

We're a trusted U.S. label manufacturer offering factory-direct prices and same-day shipping. From warehouses to packaging lines, we make it easy to get the labels you need — fast, affordable, and reliable.

We're a trusted U.S. label manufacturer offering factory-direct prices and same-day shipping. From warehouses to packaging lines, we make it easy to get the labels you need — fast, affordable, and reliable.

We make labels that work as hard as you do. Based in the U.S., our in-house manufacturing gives you full control—better quality, faster delivery, and reliable results every time. From standard formats to custom creations, we're built to deliver

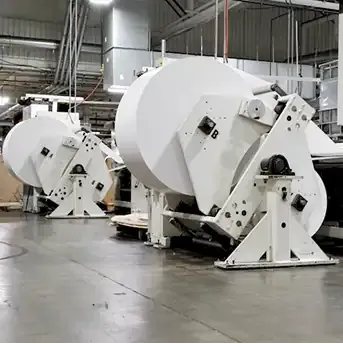

We partner with trusted paper mills to source our facestocks and liners. This gives us consistent control over quality, cost, and supply across every material we produce.

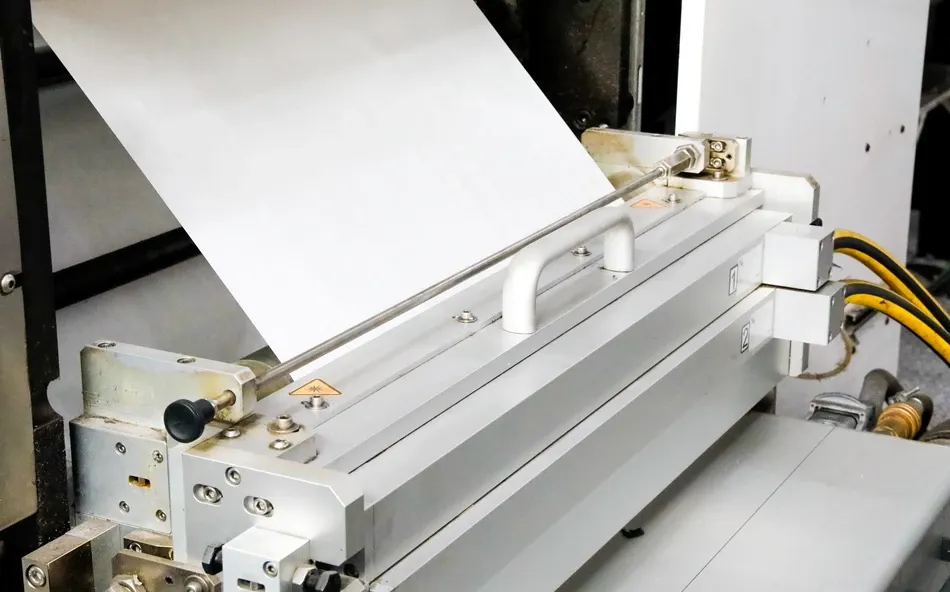

Our liners are coated with a thin, even layer of silicone that provides the clean, consistent release needed for efficient application.

Our hot melt adhesive is made in-house and coated onto the liner to meet a range of performance needs—from freezer-grade to removable applications.

Facestock, adhesive, and liner are laminated together to form a complete label construction, ready for die cutting and printing.

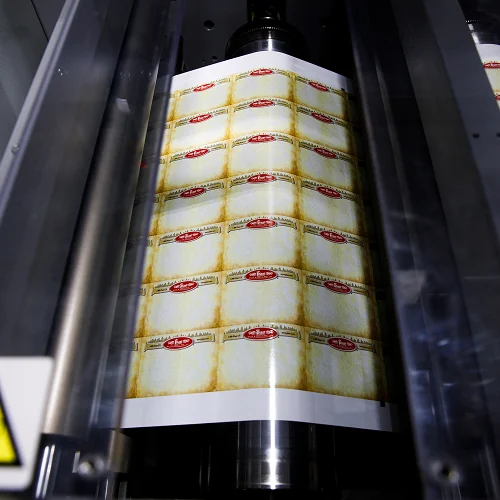

Our digital presses deliver vibrant, high-resolution graphics, while flood coating delivers full, even color coverage across the label.

Labels are cut to exact specifications using custom tooling, ensuring clean edges and consistent shape—available in roll or fanfold formats.

Each finished roll or fanfold stack is carefully inspected, counted, and packaged for accurate, on-time delivery—ready to perform.

With our BOBST digital press, we produce labels with exceptional detail, vibrant color, and consistent quality. From white ink printing to variable data and multi-SKU runs, our technology is built to handle complex, high-demand projects with ease.

Every year, Kroy diverts more than 540 tons of paper from landfills through its recycling program—minimizing waste and reducing overall environmental impact.

Independent testing by Georgia Tech's Paper Science School confirmed that Kroy's label materials and release liners are fully recyclable and re-pulpable within the brown paper stream.

Our in-house hot melt adhesive is produced using clean electric heat rather than gas-fired ovens—reducing emissions and energy consumption. For release liners, we apply UV-cured silicone enhanced with nitrogen, achieving faster curing with superior quality and lower energy use.

We manufacture entirely without solvents, eliminating hazardous emissions and maintaining a cleaner, safer production environment from start to finish.

Kroy is implementing advanced systems that recirculate heated and cooled air throughout the facility—significantly cutting electricity and gas use. Each system also double-filters the air, improving air quality across our manufacturing spaces.